Die spring

JIS Standard Die Spring

Die spring Introduction

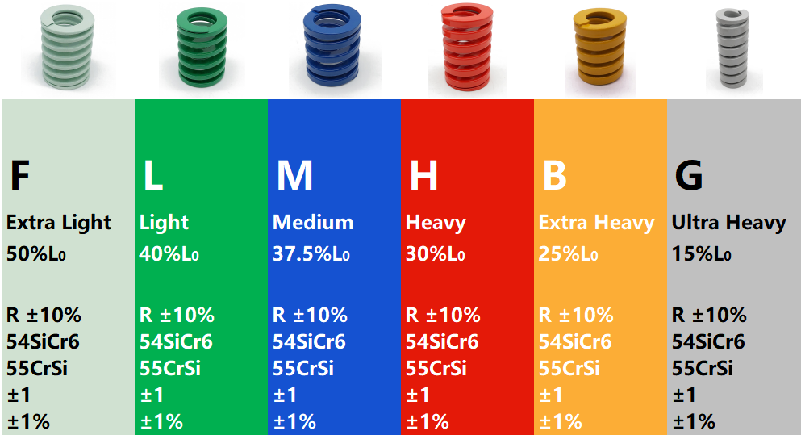

ISO 10243:2019 Die Springs including 6 serious:

Die springs

Die sorinos are heaw-duty co comopression soings pimanyused indie machinen. where hioh loads and imted space are common. These inustmalspnos are designed to wthstand higamounts of mechanical stres and are typicaly used in metal stamping dies,injection molds, and other applications where a high force is required in a confined space.

Here are some key characteristics of die springs.

High Load Capacity: Die spngs are specificaly designed to provde highforce in a relatively smalspac. They can hande sigmifcanlyhigher loads compared to tradional compresion

springs.

Long Operational Life: Die sorings are manuaclrad from hioh-quaty matenals that oer excelen durabily and fatioeresisiane, ensuino a lono operaona life even under coninuous

heavy loads.

Uniform Deflection: Die spings have a unifom pitch and diameter along the length of the col, alowing for consistent and predictable deection characteistics underload

Color-Coding: Die springs are ofen color-coded based on load capacity to facitate easy identifcation and selecion based on the required force specifcations.

Variety of sizes and Load Capacities: Die spings come in a wide range ofsizes,diameters, lengths, and load capaciies to sut iferent applications and requirements

Materials: Die sounas are tiypicaly made from hioh-capon sieel or aloy sieels, povdinathe necessany strenoth and reslience for heawy-duy aooicalions

When chosing dle sping for a speciftc applicaton, factors such as load requiremens,operating envronment. avalable space, and expeced operatonal cvdes meed to be considered to

ensure ootimal performance and longevity of the die machinery.

| Introduction | Value |

Raleigh Spring Competitive | 100% In house processes |

| Large inventory, complete specifications | |

| Competitive price | |

| Quick delivery | |

| Made to customer specification | |

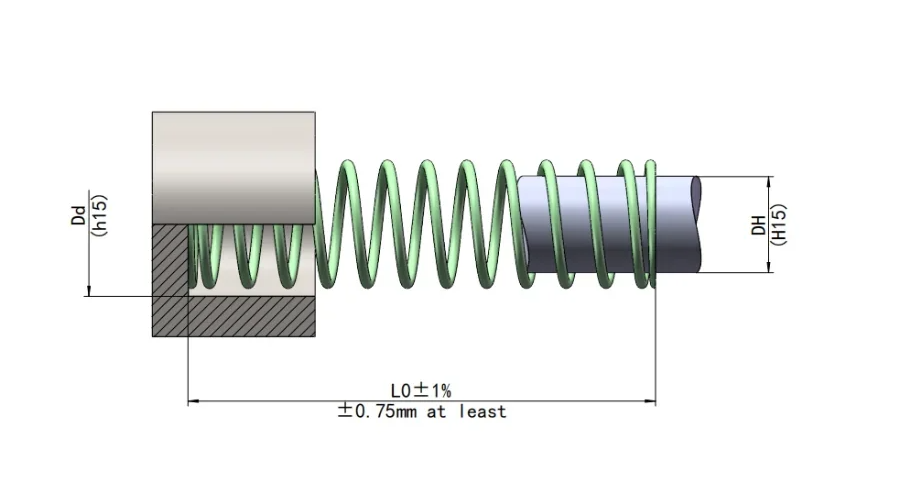

| Die Spring Diamention | According to 1S0-10243 |

| Die Spring Materials | EN10089 :54SiCr6, GBIT 1222:55CrSi |

| Die Spring Surface Treatment | 100% coating cover |

| Minimum and controlled thickness | |

| High corrosion resistance | |

| High mechanical strength |