Product center

Standard ISO Die Springs

PRODUCT DETAILS:

1-Extra Light Duty Die Spring

2-Light Duty Die Springs

3-Medium Duty Die Springs

4-Heavy Duty Die Springs

5-Extra Heavy Duty Die Springs

6-Ultra Heavy Load Die Springs

Production Process | Description |

Material Selection | The process begins with the selection of high-quality materials suitable for manufacturing mold springs. Common materials used for mold springs include carbon steel, alloy steel, and stainless steel, chosen for their strength, durability, and resistance to fatigue. |

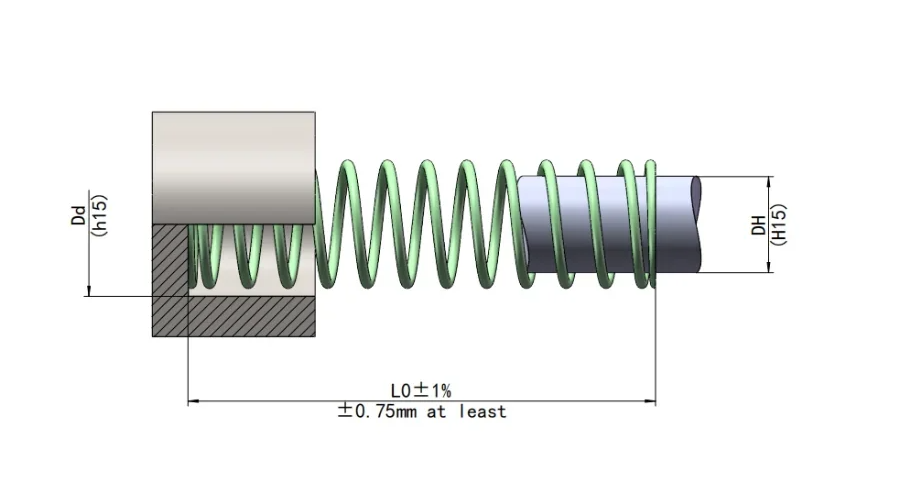

Wire Forming | The selected material is then formed into wire of the required diameter using specialized machinery. Wire forming processes can include cold drawing to achieve the desired dimensions and mechanical properties. |

Coiling | The wire is fed into a coiling machine, where it is tightly wound around a mandrel to form the coil shape characteristic of compression springs. This process is carefully controlled to ensure the proper pitch and diameter of the coils. |

Heat Treatment | After coiling, the springs undergo heat treatment to enhance their mechanical properties, including stress relief and the establishment of the desired spring hardness and resilience. This process typically involves heating the springs to a specific temperature and then cooling them at a controlled rate. |

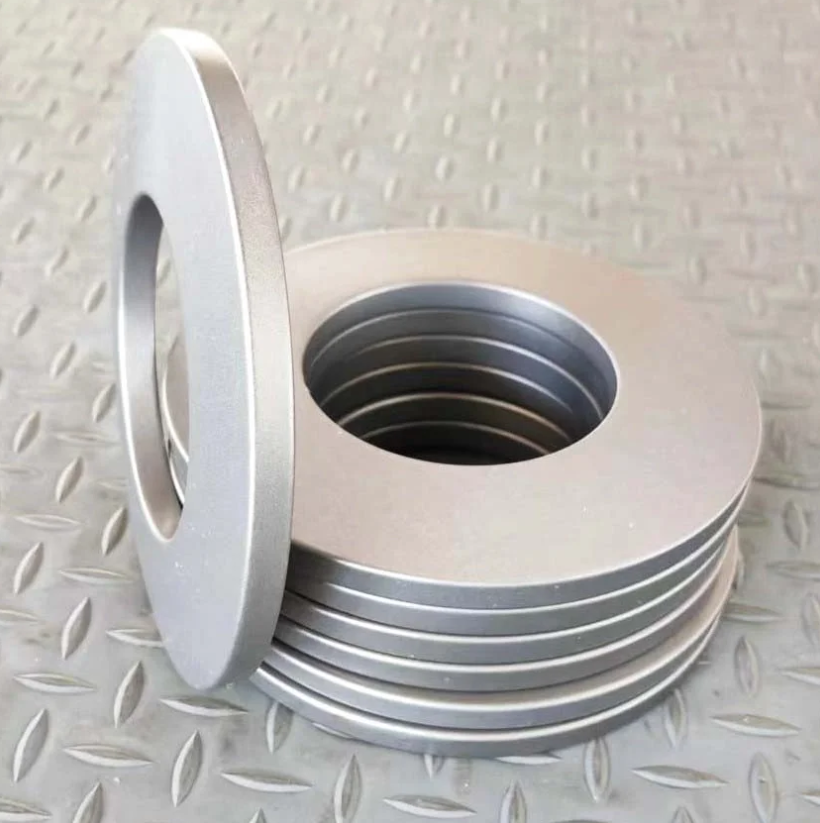

Grinding & Finishing | Once the heat treatment is completed, the springs may undergo grinding and finishing processes to achieve precise dimensions, smooth surfaces, and consistent spring ends. This step ensures that the springs meet tight tolerances and surface finish requirements. |

Color Coding | Die springs are color-coded based on load capacity or other specifications for easy identification and selection. |

Quality Control | Throughout the production process, rigorous quality control measures are implemented to inspect the springs for dimensional accuracy, surface quality, and mechanical properties. This may involve various testing methods, such as load testing, hardness testing, and dimensional measurements. |

Packaging | Finally, the finished mold springs are packaged according to industry standards and prepared for shipment to customers or distribution centers. |