Product center

Metric Belleville-50CrVA

PRODUCT DETAILS:

1. Definition

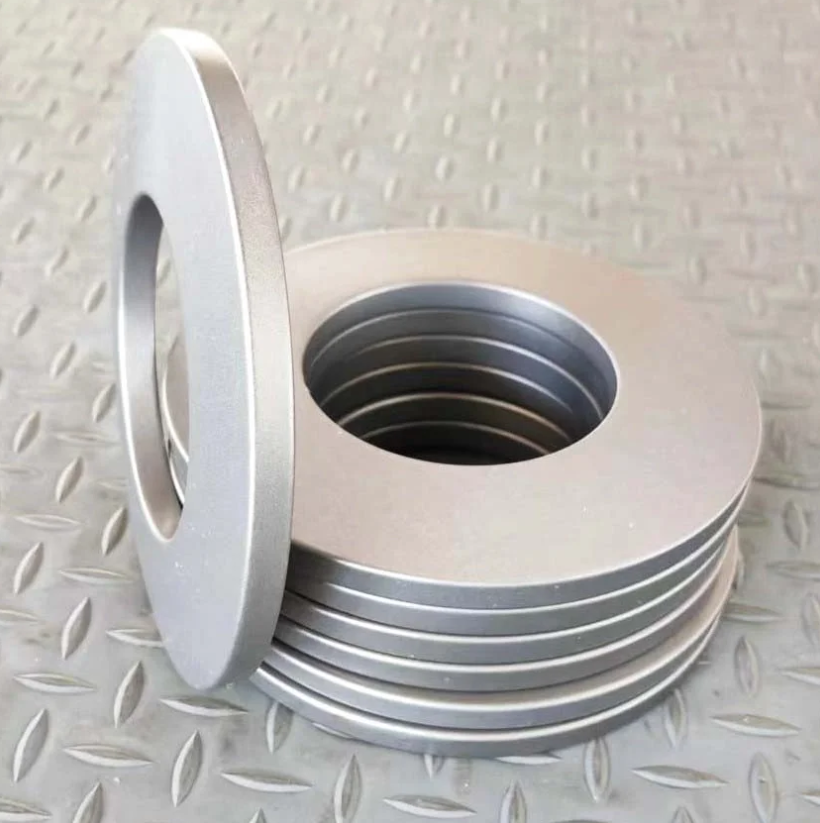

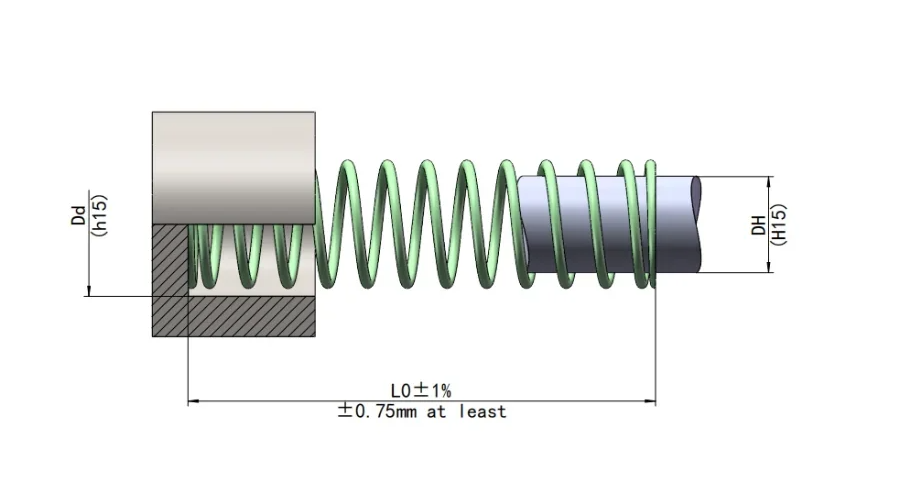

Disc spring, referred to as disc spring, is like a bottomless metal plate, which can bear axial load. It is usually an elastic element processed by metal steel strip, steel plate or forging billet.

2. Characteristics of Disc Spring

1) The size is small in the direction of the load, and it can bear a large load with a small deformation. The axial space is compact and has a large deformation capacity.

2) It has the characteristic of variable stiffness. According to different h0/t, the characteristics of approximate straight line, decreasing type, increasing type, zero stiffness and even negative stiffness can be obtained.

3) Free and convenient combination, can be standardized production, easy to use, maintain and manage.

3. Structural form

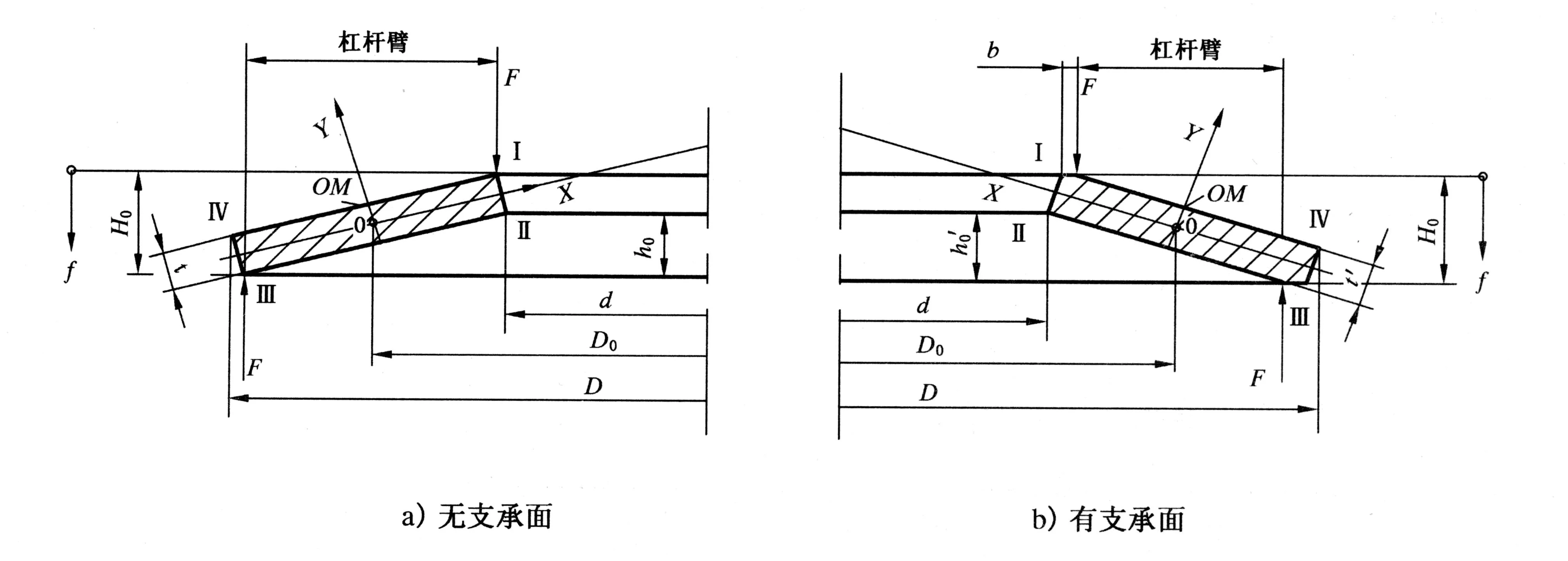

Ordinary disc springs are divided into two types according to the supporting structure: no bearing surface and bearing surface, as shown in figure.

4. The technical requirements of the disc spring

1) The material is recommended to use 60Si2MnA or 50CrVA in the GB/T1972-2005 standard, and stainless steel, heat-resistant steel or other copper alloys, titanium alloys, nickel-based, cobalt-based alloys, etc. can also be used.

2) Limit deviation of size and shape:

Chinese standards divide the size and load accuracy of disc springs into first-level and second-level precision. Dimensions include diameter (inner and outer diameters), thickness, and free height.

3) Shape and position limit deviation: The national standard only has surface roughness, and these specific data are specified in GB/T1972-2005.

4) There are clear requirements for surface treatment, heat treatment and pressure treatment. Whether the surface is oxidized or phosphated, no burrs, cracks and scars that are harmful to use are allowed. If quenching and tempering are required, the number of quenching shall not exceed twice, the hardness shall be in the middle of 42HRC~52HRC, and the depth of unilateral decarburization shall not exceed 5% of its thickness for Group 1 disc springs, and shall not exceed 5% for Group 2 and Group 3 disc springs. More than 3% of its thickness (maximum not exceeding 0.15mm).

5) Strong pressure treatment is a necessary process. The treatment method is to compress the spring with a load of ≮2Ff=0.75h0 for a duration of ≮12h, or to compress it for a short time, and the number of compression is ≮5 times.

6) The special technical requirements for special surface anti-corrosion treatment and strengthening treatment (such as fatigue, relaxation, creep, etc.) are stipulated by the agreement between the two parties, and are not mandatory provisions of the national standard.

7) According to the requirements of national standards, the disc spring manufacturing process and its thickness are divided into three groups:

Group | t | With flat bearings and reduced thickness |

1 | <1.25 | No |

2 | 1.25 ≤ t ≤6 | No |

3 | 6 <t ≤ 14 | Yes |

Raleigh Spring can also customize according to your special requirement.